Understanding Military Sales – Getting Started

Most lubricant manufacturers at one time or another have inquired to whether their lubricants, hydraulic fluids, or greases are procured by the U.S. Military. Without a working knowledge of the U.S. Department of Defense’s (DoD) procurement branch (The Defense Logistics Agency), and their procedures, policies, information sources, and slow moving processes, manufacturers’ forays into military sales are usually are short lived and end with a “That’s not for us!” conclusion. However, with patience and perseverance, a constantly high quality product (and a love of acronyms!), companies that succeed find supplying the military a rewarding market.

Fortunately, learning the basics, especially where and how to start, has gotten easier for lubricant manufacturers over the past 10 years. Understanding the procurement principals and procurement process can significantly ease the frustration and time spent entering into military sales.

Until the mid 2000’s, almost all military procurement was done through a cumbersome paper-based bid process with the DoD. Contracts were awarded either on a “spot basis”, or through a one year (with multiyear options) Long Term Agreement (LTA). The finished packaged lubricants were usually shipped

directly to one of the two major U.S. Government depots, either Richmond VA or Tracy CA. In 2007, through the congressional mandated Base Realignment and Closure Act (BRAC), the DoD “privatized” the procurement, warehousing, and distribution of all packaged petroleum products, bulk oil shipments, lubricants, and chemicals under the new “POLCHEM” contract program. This 10 year contract (5 year base, with a 5 year option), with an overall contact value budgeted at $6 billion, was awarded to SAIC of Fairfield, NJ. Under the POLCHEM contract, SAIC, with their 8 strategically located U.S. warehouses, was now responsible for all procurement, warehousing, inventory level management, supplier base management, and delivery of the POLCHEM products to U.S. military and federal civilian agency locations around the globe.

SAIC, partnered with DLA’s sub-agency Defence Supply Center-Richmond, is the prime contractor with the responsibility of the procurement of the 4,000+ NSNs specified in the POLCHEM contract. A NSN (National Stock Number) is a unique 13 digit numeric code for identifying standardized items procured for the U.S. Department of Defense. NSNs are also recognized by all NATO countries. Every lubricant product that is procured for the U.S. Military has its own NSN. Even the same product in a different package/container has a unique NSN!

All NSNs are grouped into Federal Supply Classes (FSCs). A FSC is a 4 digit field used to group products in logical families. The first 4 digits of a NSN designate the FSC. The two principal Federal Supply Classes (FSC) managed by SAIC and applicable to the Lubricant Industry are 9150 (Oils and Greases: Cutting, Lubricating, and Hydraulic Fluids), and 6850 (Miscellaneous Chemical Specialties).

Determining whether your product is procured for the military can be confusing. The product can either be listed as a commercial item, or fall under a military specification (MILSPEC), or sometimes both! Either way, if the product is procured, a NSN exists for that product. Keep in mind that military packaging requirements very often differ from the commercial/industrial requirements. The military likes their lubricants and oils in metal can packaging, so the need for your product in the standard commercial one gallon plastic container might not be a listed NSN procurement item, but the same product in a metal can might have significant volume potential. As you might guess, military packaging and labeling is an art. It really is a time-in-grade process. In the beginning, be prepared to ask a lot of questions of the prime and secondary contractors, as well as DLA. Fortunately, all involved in the supply chain realize we are all pulling on the same side of the rope, and friendly help is usually just a phone call away.

Some 9150 products are procured by tradename, while most other products are procured by MILSPEC. A MILSPEC (or “military specification”) is a U.S. Department of Defense standard used to achieve strict lubricant standardization objectives. Most of these lubricants are “Critical Application” items. These are lubricants/fluids that are critical for flight control, weapons platform functionality, and surface warfare propulsion. Supplying a “Critical Application” MISLPEC requires a lengthy Qualification process, with the end result having your product listed on the “Qualified Product List” or “QPL”. The “QPL” is a DoD controlled list of companies and their unique formulations that have been certified by the military custodial authority, whether it be Naval Sea Command, Naval Air Command, the Air Force, or the Army, that meets or exceed all the physical properties and performance requirements specified in the product’s applicable MILSPEC. The physical properties tests that need to be met, as well as the performance requirements, can be upwards of 30 different tests! As one can guess, meeting a MILSPEC

can be a formulator’s nightmare. But the effort has its rewards. Once issued a QPL, the company has the ability to bid and be awarded QPL required contracts and spot orders.

Access to FSCs, NSNs, Commercial Items, and MILSPEC databases are available on the web. A little time and effort spent researching your products with these resources could open up new horizons in military sales!

For more information on Radco MILSPEC products please reach out to our MILSPEC team.

All heat transfer fluids degrade over time due to thermal stress. These degradation by-products, referred to by most fluid manufacturers as “high boilers” and “low boilers”, are molecular fragments formed when the heat transfer fluid’s molecular bonds are broken. These fragments can polymerize with other fragments, creating extremely large molecules which in turn lead to the formation of high molecular weight carbon particulates. These particulates are commonly referred to “coke” or “sludge”.

High and low boilers, carbon particulates, and inorganics have very little of the heat transfer efficiency of the original heat transfer fluid. The presence of high levels of carbonized and inorganic material can cause mechanical problems in the system such as seal and gasket leakage and/or failure, heater tube fouling (decreasing the amount of BTUs transferred to the fluid), and increased pressure drop (due to coking on pipe surfaces). Carbonization in the fluid also specifically affects the fluid’s heat transfer properties such as viscosity and density, lowering the heat transfer coefficient. Therefore, the elimination and/or reduction of carbon and organics in the heat transfer fluid will lead to longer periods of time between fluid change-outs, higher fluid efficiency, and decreased downtime required for system maintenance.

All heat transfer fluids degrade over time due to thermal stress. These degradation by-products, referred to by most fluid manufacturers as “high boilers” and “low boilers”, are molecular fragments formed when the heat transfer fluid’s molecular bonds are broken. These fragments can polymerize with other fragments, creating extremely large molecules which in turn lead to the formation of high molecular weight carbon particulates. These particulates are commonly referred to “coke” or “sludge”.

High and low boilers, carbon particulates, and inorganics have very little of the heat transfer efficiency of the original heat transfer fluid. The presence of high levels of carbonized and inorganic material can cause mechanical problems in the system such as seal and gasket leakage and/or failure, heater tube fouling (decreasing the amount of BTUs transferred to the fluid), and increased pressure drop (due to coking on pipe surfaces). Carbonization in the fluid also specifically affects the fluid’s heat transfer properties such as viscosity and density, lowering the heat transfer coefficient. Therefore, the elimination and/or reduction of carbon and organics in the heat transfer fluid will lead to longer periods of time between fluid change-outs, higher fluid efficiency, and decreased downtime required for system maintenance.

1. Baffled tanks

2. Straight Leg Tanks

3. Flow Through (or “Surge” Tanks)Surge tank designs essentially are tanks serving as a receiver for thermal fluid from the user with the main circulating pump drawing thermal fluid from the bottom of the tank for return to the heater. This design offers no oxidation protection and in fact increases oxidation due to the aeration of the thermal fluid in the tank itself. This is a poor design for extended thermal fluid use but does provide excellent thermal system venting capabilities during startup and extended operation.The baffled tank has three chambers or baffles. As the thermal fluid is heated, expansion of the fluid occurs from the first chamber into the second, and then into the main tank. In a properly sized expansion tank, when a thermal system is properly filled with cold thermal fluid there will be a significant level of fluid in the main baffle. With this type of design, thermal fluid in the main baffle rarely, if ever, co-mingles with hot fluid in the primary thermal system heat transfer loop because of inherent system fluid pressures. The fluid in the main baffle is significantly cooler than in the other baffles, forming a thermal blanket over the fluid in the primary thermal system heat transfer loop materially decreasing degradation of the thermal fluid due to oxidation.

As a general rule, in liquid phase thermal systems the expansion tank volumes should be approximately 26% – 30% of the total estimated volume of thermal fluid in the thermal system. The properly sized expansion tank should be approximately 1/4 full at startup temperatures and 3/4 full at operating temperatures.As the thermal system is brought up to operating temperature, the straight leg design allows the expanded thermal fluid to enter directly into the bottom of the main expansion tank by means of a small diameter pipe bypassing the flow-through valves under the expansion tank on the pump suction side of the tank Since the expansion tank is located at the highest point of the thermal system, the bulk of the thermal fluid will flow directly to the heater. Similar inherent fluid pressures as seen in the baffled tank keep thermal fluid in the expansion tank from co-mingling freely with fluid in the primary thermal system heat transfer loop. This type of design does not offer the same oxidation protection as the baffled design and, depending on system temperatures, an inert gas blanket may be required. Excellent thermal system venting may be accomplished by configuring the main line tank bypass valving to run through the expansion tank.

1. Baffled tanks

2. Straight Leg Tanks

3. Flow Through (or “Surge” Tanks)Surge tank designs essentially are tanks serving as a receiver for thermal fluid from the user with the main circulating pump drawing thermal fluid from the bottom of the tank for return to the heater. This design offers no oxidation protection and in fact increases oxidation due to the aeration of the thermal fluid in the tank itself. This is a poor design for extended thermal fluid use but does provide excellent thermal system venting capabilities during startup and extended operation.The baffled tank has three chambers or baffles. As the thermal fluid is heated, expansion of the fluid occurs from the first chamber into the second, and then into the main tank. In a properly sized expansion tank, when a thermal system is properly filled with cold thermal fluid there will be a significant level of fluid in the main baffle. With this type of design, thermal fluid in the main baffle rarely, if ever, co-mingles with hot fluid in the primary thermal system heat transfer loop because of inherent system fluid pressures. The fluid in the main baffle is significantly cooler than in the other baffles, forming a thermal blanket over the fluid in the primary thermal system heat transfer loop materially decreasing degradation of the thermal fluid due to oxidation.

As a general rule, in liquid phase thermal systems the expansion tank volumes should be approximately 26% – 30% of the total estimated volume of thermal fluid in the thermal system. The properly sized expansion tank should be approximately 1/4 full at startup temperatures and 3/4 full at operating temperatures.As the thermal system is brought up to operating temperature, the straight leg design allows the expanded thermal fluid to enter directly into the bottom of the main expansion tank by means of a small diameter pipe bypassing the flow-through valves under the expansion tank on the pump suction side of the tank Since the expansion tank is located at the highest point of the thermal system, the bulk of the thermal fluid will flow directly to the heater. Similar inherent fluid pressures as seen in the baffled tank keep thermal fluid in the expansion tank from co-mingling freely with fluid in the primary thermal system heat transfer loop. This type of design does not offer the same oxidation protection as the baffled design and, depending on system temperatures, an inert gas blanket may be required. Excellent thermal system venting may be accomplished by configuring the main line tank bypass valving to run through the expansion tank.

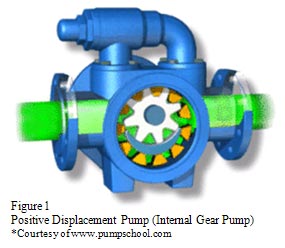

Conversely, positive displacement pumps, such as the internal gear pump shown in Figure 1, cannot dispel fluid in great quantities. Instead, positive displacement pumps are capable of delivering a constant, pulse-free flow through the system, independent of variations in system pressure. Centrifugal pumps can operate proficiently under certain pressures, but their efficiency significantly drops as system pressure increases. Most heat transfer systems are designed for operation under 50 psi, in which case, both centrifugal and positive displacement pumps can be used. Centrifugal pumps can be sized for head pressures up to 55 psi (125 ft.)The next considerable aspect of pump selection is system capacity. The main advantage of centrifugal pumps is their ability to transfer large volumes of liquid (up to 120,000 gallons per minute.) Processes can even be designed with several centrifugal pumps in parallel to maximize fluid discharge.

Net Positive Suction Head, more commonly referred to as “system pressure,” is the sum of several factors determined by system design. The NPSH is determined by the following:

Conversely, positive displacement pumps, such as the internal gear pump shown in Figure 1, cannot dispel fluid in great quantities. Instead, positive displacement pumps are capable of delivering a constant, pulse-free flow through the system, independent of variations in system pressure. Centrifugal pumps can operate proficiently under certain pressures, but their efficiency significantly drops as system pressure increases. Most heat transfer systems are designed for operation under 50 psi, in which case, both centrifugal and positive displacement pumps can be used. Centrifugal pumps can be sized for head pressures up to 55 psi (125 ft.)The next considerable aspect of pump selection is system capacity. The main advantage of centrifugal pumps is their ability to transfer large volumes of liquid (up to 120,000 gallons per minute.) Processes can even be designed with several centrifugal pumps in parallel to maximize fluid discharge.

Net Positive Suction Head, more commonly referred to as “system pressure,” is the sum of several factors determined by system design. The NPSH is determined by the following:

Heat transfer fluids are vital to many processes worldwide. To ensure their ongoing, safe operation, it is important to protect the fluid not only during regular operation but also during system startup and shutdown. Here are some guidelines to ensure a smooth startup and shutdown of your heat transfer system.

Heat transfer fluids are vital to many processes worldwide. To ensure their ongoing, safe operation, it is important to protect the fluid not only during regular operation but also during system startup and shutdown. Here are some guidelines to ensure a smooth startup and shutdown of your heat transfer system.

Quick disconnect valves speed the process of loading and unloading.

Quick disconnect valves speed the process of loading and unloading.

Founded in 1944 as the National Sanitation Foundation, NSF International, Ann Arbor, Mich., is known for the development of standards, product testing and certification services in the areas of public health, safety and protection of the environment. NSF became involved when the USDA decided that it would no longer maintain its list. At first, NSF acted as record keeper to ensure the list was available for review. Now, the organization has taken an active role to refine the list. NSF created the Non-Foods Compound Group to define the use of heat transfer fluid, fluid additives and lubricants, as well as other materials, separately for their specific applications.Likewise, until recently, the United States Department of Agriculture (USDA), Washington, had its own regulations, which included mineral oils used as machinery lubricants and release agents to prevent meat from sticking to grills. The reference, H1 status, was used to indicate that the oil was acceptable for use in meat and poultry establishments and could have incidental food or feed contact. Again, these same mineral oils can be part or all of what is used as a “hot oil” for heat transfer.

Kenji Yano, program manager of the nonfood compounds registration program explains, “The term ‘food-grade’ is not used. …Instead ‘incidental contact’ (HT1) is used as opposed to ‘nonfood contact’ (HT2) compounds.” NSF keeps this list online, on CD and in its “White Book,” which is published annually.

Founded in 1944 as the National Sanitation Foundation, NSF International, Ann Arbor, Mich., is known for the development of standards, product testing and certification services in the areas of public health, safety and protection of the environment. NSF became involved when the USDA decided that it would no longer maintain its list. At first, NSF acted as record keeper to ensure the list was available for review. Now, the organization has taken an active role to refine the list. NSF created the Non-Foods Compound Group to define the use of heat transfer fluid, fluid additives and lubricants, as well as other materials, separately for their specific applications.Likewise, until recently, the United States Department of Agriculture (USDA), Washington, had its own regulations, which included mineral oils used as machinery lubricants and release agents to prevent meat from sticking to grills. The reference, H1 status, was used to indicate that the oil was acceptable for use in meat and poultry establishments and could have incidental food or feed contact. Again, these same mineral oils can be part or all of what is used as a “hot oil” for heat transfer.

Kenji Yano, program manager of the nonfood compounds registration program explains, “The term ‘food-grade’ is not used. …Instead ‘incidental contact’ (HT1) is used as opposed to ‘nonfood contact’ (HT2) compounds.” NSF keeps this list online, on CD and in its “White Book,” which is published annually.